05.08.2019

0600

Tools:

- The CD Recycling Center of America: http:// http://cdrecyclingcenter.org/

- A few large envelopes

- A marker to label each envelope

Materials:

- Old CDs (Compact Discs)

- Old DVDs (Digital Versatile Discs)

- Old CD and DVD cases

When it comes to recycling CDs and DVDs, the information was never really clear as to where to recycle these type of materials. I did some research and found out that there is The CD Recycling Center of America, who provides that exact service.

Each year, billions of CDs and DVDs are manufactured, while millions of these discs end up in landfills and incinerators. If you use, sell, promote, distribute, or manufacture compact discs, it is your responsibility to promote how to recycle them. Compacts Discs, when recycled properly, will stop unnecessary pollution, conserve natural resources, and help slow global warming. Spread the word to help us save the world we all live in.

For those companies that require a certificate of destruction, that service is available as well.

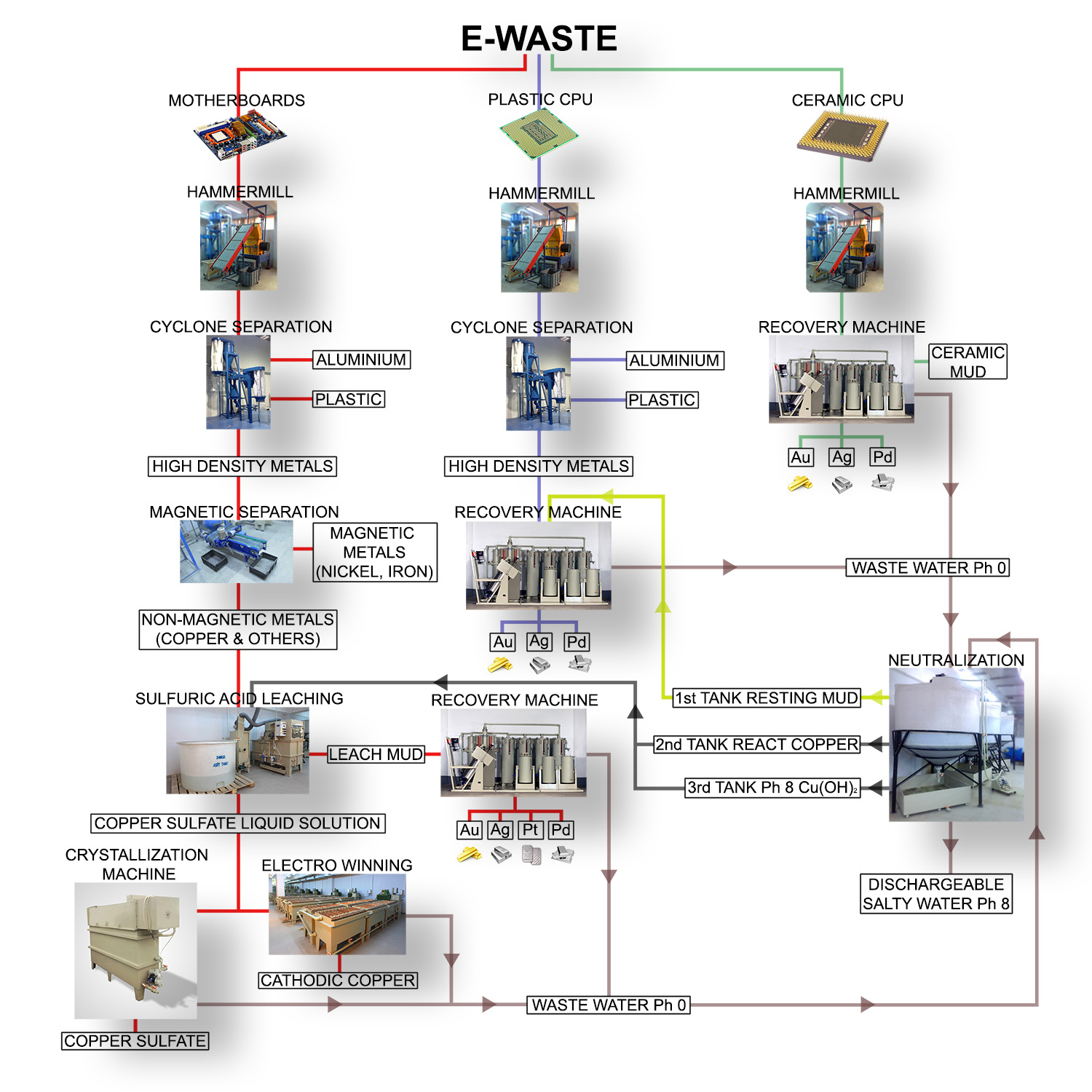

The CD Recycling Center of America collects old CDs, DVDs and cases and securely deconstructs the items. CDs and DVDs contain different metals and materials that should be separated safely. They contain materials such as:

- Aluminum-the most abundant metal element in the Earth’s crust. Bauxite ore is the main source of aluminum and is extracted from the Earth.

- Polycarbonate-a type of plastic, which is made from crude oil and natural gas extracted from the Earth.

- Lacquer-made of acrylic, another type of plastic.

- Gold-a metal that is mined from the Earth.

- Dyes-chemicals made in a laboratory, partially from petroleum products that come from the Earth.

- Other materials such as water, glass, silver, and nickel.

There are different programs offered to different types of business and institutions, so the parameters of how they will receive your recycling material will differ. All you have to do, is scroll down to your category and pick the program that fits your needs. They have programs for:

- Individuals / households

- Schools

- Libraries

- Musicians

- Recording Studios

- Radio & Television

- Duplicators/Replicators

- Small Businesses

- Recycling companies

Since I’m recycling as a household, I checked the “Programs” tab, and scrolled down to the “Individuals / households” section, to read my requirements.

They do ask that the broken disc cases be kept separated from the other cases. I separated my shipment into four categories, and labeled them as needed:

- Discs = ” CDs / DVDs / HD-DVD / Blu-ray Discs Only”

- Cases = ” Cases Only”

- Paper covers/inserts = “CD paperwork Only”

- Sleeves = “Discs Sleeves Only”

- Broken Cases = “Broken Cases Only”

Since I live in California, my mailing destination was Salem, New Hampshire. I packed up my envelope of items and sent it out:

The CD Recycling Center

CD Recycling Center of America

68E Stiles Road

Salem NH 03079

By recycling your old CDs, DVDs and cases with the CD Recycling Center of America, you’ll generate less trash and keep the landfill free of the harmful metals and materials.

Learn more about this program at http:// http://cdrecyclingcenter.org/